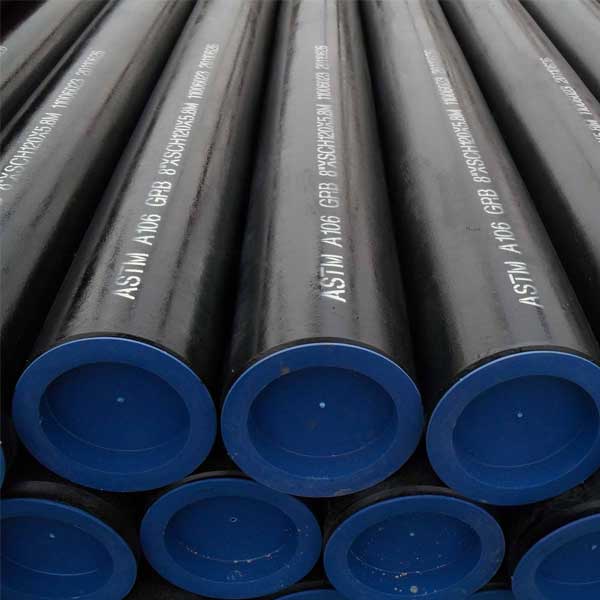

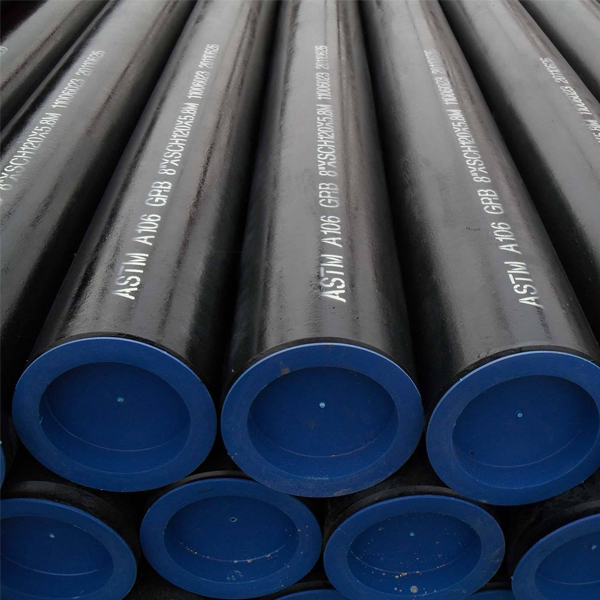

Product:Line Pipe, API Line Pipe, Seamless Line Pipe, Carbon Steel Line Pipe

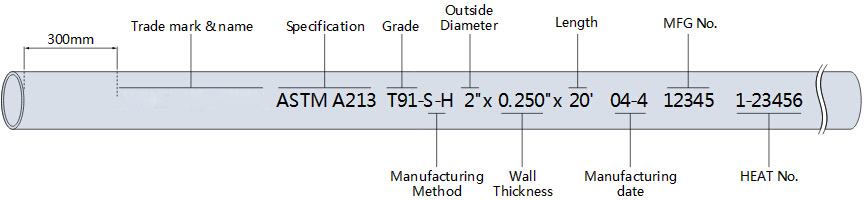

Specification:

Outer Diameter(OD): 73-630mm

Wall Thickness(WT): 6-35mm

LENGTH: 5.8/6/11.8/12m

Pipe Standard:

API 5L PSL1/PSL2 Gr.A,Gr.B,X42,X46,X52,X56,X60,X65,X70

API 5L PSL1/PSL2 L210,L245,L290,L320,L360,L390,L415,L450,L485

End: Square Ends/Plain Ends (straight cut, saw cut, torch cut),Beveled/Threaded Ends

Surface:Black Painting/Oil Painting/Anti-Rust oil/Anti-Corrosive Coating

Packing: Bundled,Plastic Caps Plugged,Waterproof Paper/Bag Wrapped

Application:For Transportation in petroleum and natural gas industries

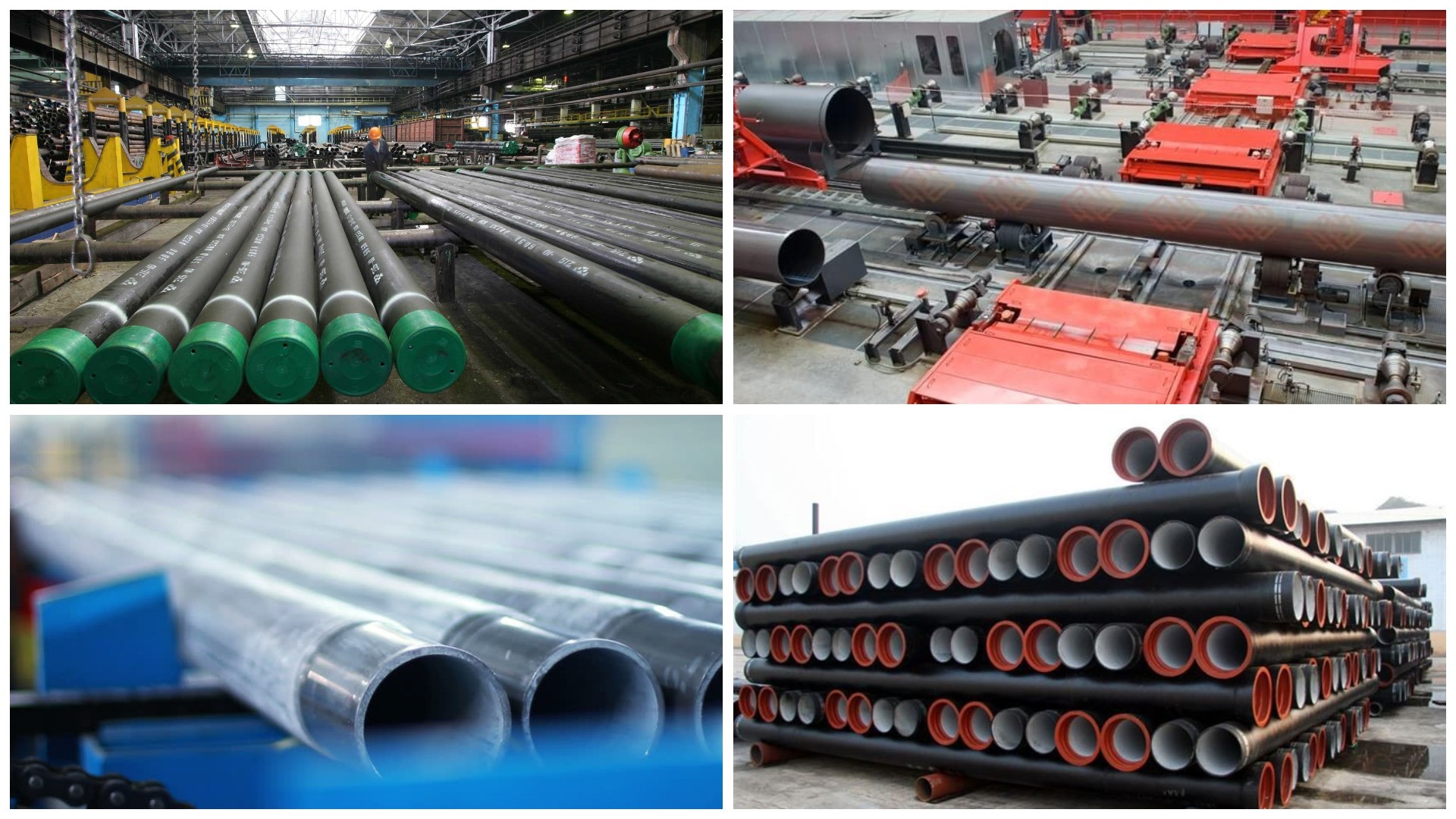

Line pipe is a tube made of high strength carbon steel. It is typically manufactured according to the API 5L metallurgical specification developed by the American Petroleum Institute (API). The raw material can be either seamless or welded carbon steel or stainless steel piping. This product can be used to build pipelines that transport a variety of resources including natural gas, oil, petroleum, and water. API 5L line pipe is available in various diameters ranging from two inches to 48 inches. Its size and diameter required for a pipeline vary according to the amount of gas or liquid that it intended to carry and the pressures it must withstand.

Seamless Line Pipe

Steel Grade: B, X42, X52, X60, X65, X70

Dimension: 1"/2" - 24"

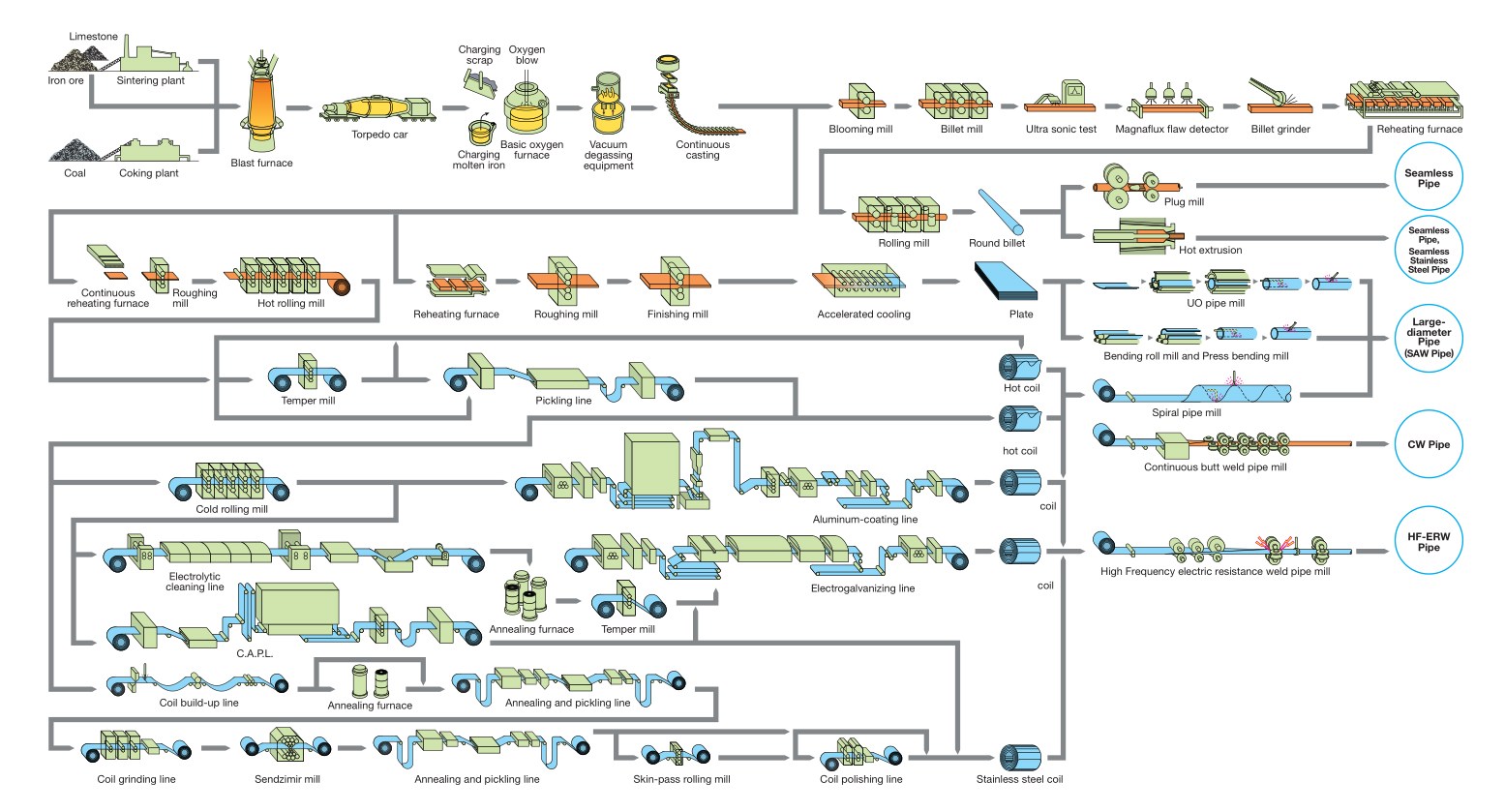

Process:hot rolling, hot expanding

Welding Line Pipe

Steel Grade: B, X42, X52, X60, X65, X70, X80

Dimension: 2" - 30"

Process: ERW, SSAW, LSAW, HFW, JCOE.

Standard: API 5L / ISO 3183 Hot Rolled

Type: Seamless / ERW / Welded / Fabricated / CDW

Outer Diameter Size: 3/8" NB To 30" NB (Nominal Bore Size)

Wall Thickness: Schedule 20 To Schedule XXS (Heavier On Request) Up to 250 mm Thickness

Length: 5 To 7 Meters, 09 To 13 Meters, Single Random Length, Double Random Length And Customize Size.

Pipe Ends: Plain Ends / Beveled Ends / Coupling

Surface Coating: Epoxy Coating / Colour Paint Coating / 3LPE Coating.

Grades: API 5l Grade B X42, API 5l Grade B X46, API 5l Grade B X52, API 5l Grade B X56, API 5l Grade B X60, API 5l Grade B X65, API 5l Grade B X70

Español

Español English

English