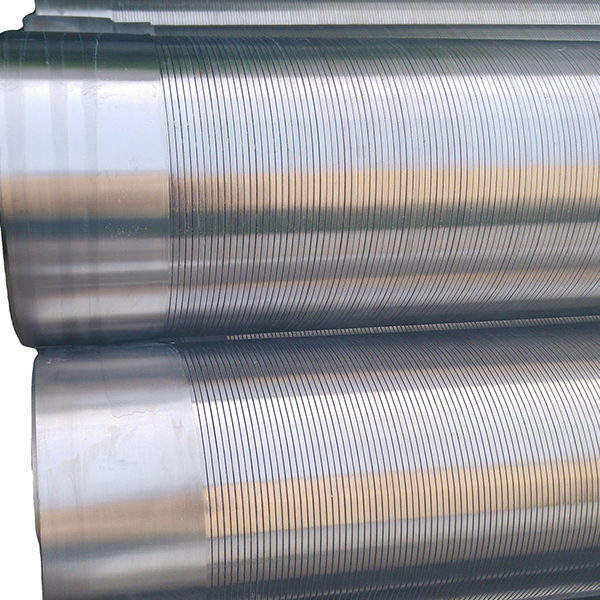

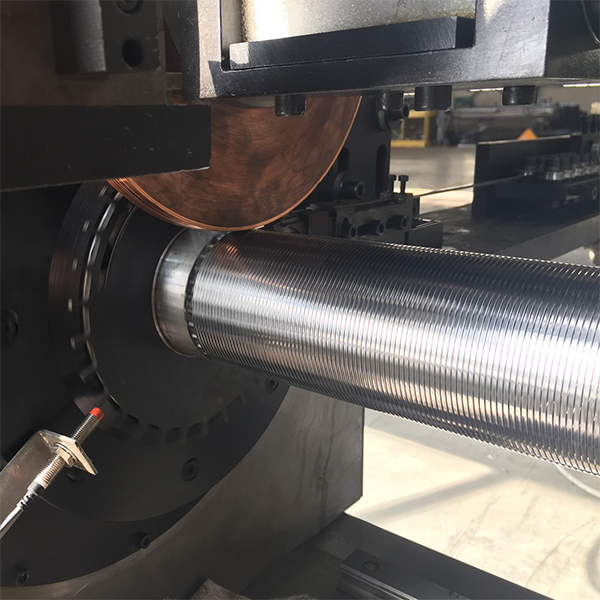

wire wrapped Screen Tube is manufactured by a v or wedge shaped wire around an internal array of longitudinal support rods. Each intersecting point of these wire is fusion welded.

The v or wedge shaped profile wire wraps around the support rods over the full length of the screen creating a continuous slot opening, hence the screen allows water (oil) to enter your well freely in ample quantities,while at the same time keeps the majority of sand and gravel out of the well

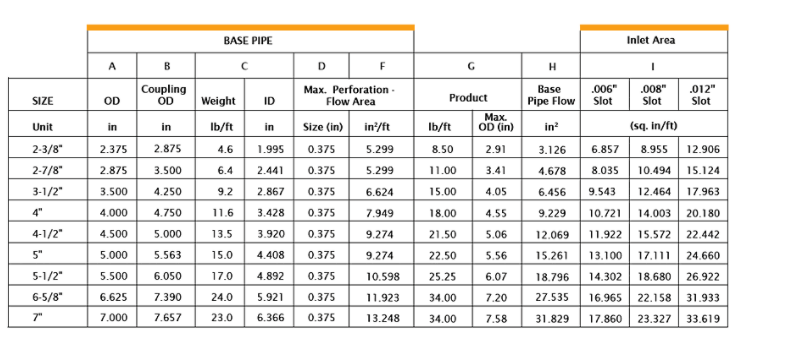

Technical Specification of Johnson wedge wire wrapped Screen

Application:Municipal water source well, Domestic well, Agricultural water well, Groundwater, Industrial water well.

Grade: Single layer pipe can be used for 100M~1000M deep Wells according to different rib sizes

End Connection: wire buckle or straight pipe head

Standard Length: 2.93m/root; 5.85 meters/root

Nominal Diameter(mm): 1.5 “(38), 2 (50),” 3 “(73), 4 (108),” 6 “(159), 8 (219),” 10 “(250), 12 (273),” 14 “(325).

Slot(mm): 0.1, 0.15, 0.25, 0.5, 0.76, 1.0, 1.25, 1.50, 1.75, 2.0, 2.5, 3.0, 4.0, 5.0

The well filter pipe can adapt to a variety of environmental conditions, the use of very corrosion-resistant materials, can prevent the dirt on the surface of the filter pipe, can ensure the maximum water extraction area and sufficient strength.

Areas of application: can be used with deep well pump, submersible pump, can be used in water treatment equipment, environmental protection, the water of the sea into the industrial water and domestic water desalination process, water treatment, water softening treatment, petroleum chemical industry, the terminal filtration of oil products and chemical acid, alkali liquid filtration, alcohol and other organic solution of recycling. It can also be used for hydrogeological exploration, drilling, well sinking, construction, reservoir precipitation, foundation deep digging precipitation, geothermal development and utilization, mineral water development and utilization, geothermal air conditioning, repair of bad Wells, water intake from underground water sources.

Features:

1. Filters with higher porosity are better suited for building efficient water, oil, and gas Wells.

2. The filter pipe with low operating cost and high porosity is more conducive to the infiltration of groundwater. The abundance of water reduces the depth of the water level, thus reducing energy consumption, especially for fine and silt formations in Wells.

3. Reduce the wear of the pump. Under the same conditions, the higher porosity makes the speed of groundwater infiltration into the filter pipe much slower than that of other filtration devices, so as to avoid the sand entering the filter pipe under greater water pressure and reduce the wear of the pump.

4. The opening area of the well filter pipe is large, and the proportion of the filter area is high, the maximum can reach 60%.

5. V-shaped filament filter pipe is easy to backwash, long service life, safe and reliable, and low comprehensive cost.

6. The larger filtration area can relatively reduce the pressure of water infiltration, which can prevent sand particles from entering the well pipe under high water pressure, thus reducing the friction between sand particles and equipment, reducing wear and improving the service life of equipment.

Español

Español English

English