El alto grado de resistencia a la corrosión del níquel se debe a que es un metal relativamente noble dentro de la serie de metales electroquímicos galvánicos. La adición de cromo, molibdeno, cobre y otros elementos a las aleaciones les otorga una resistencia aún mayor a la oxidación y la corrosión, lo que hace posible su uso en una gama más amplia de aplicaciones. Los tubos y tuberías sin costura hechos de aleaciones de níquel resistentes a la corrosión son la primera opción para muchas aplicaciones debido a su excelente resistencia a varios ácidos (ácido sulfúrico, ácido clorhídrico, ácido fosfórico) y soluciones alcalinas. Un aumento adicional de elementos de aleación específicos (como cromo, molibdeno, tungsteno, titanio, aluminio, niobio, etc.) mejora las características de alta temperatura y alta resistencia de los aceros austeníticos. La desventaja de los aceros inoxidables austeníticos radica en el hecho de que estos elementos tienen una solubilidad reducida. Para compensar este efecto y alcanzar el resultado deseado, se puede aumentar la concentración de níquel. Los tipos de aleación más alta de aleaciones a base de níquel de alta temperatura contienen solo una concentración de hierro muy baja.

Tipo de tubería: Tubería de acero al níquel, Tubería sin soldadura de aleación de níquel, Tubería de aleación de níquel

Diámetro externo:(OD:) NPS 1/8 -80, BN 6 - 2000, 10.3 - 2030 , Alao capilary

Espesor de pared(WT): Sch5s-Sch160s, SchXXH, STD,XS,XXS

Calendario :SCH 5 , 10, 20 , 40 , STD , 60 , 80 , XS

longitud:Single Random, Double Random & Cut Length

Estándares :GB,AISI,ASTM,DIN,EN,SUS,UNS etc

Especificaciones :ASTM / ASME SB 163 / 165 / 167 / 464/ 517 / 619 / 622 / 626 / 704 / 705.

Forma: redonda, cuadrada, rectangular, hidráulica, etc.

Tipo: Tubos sin costura / ERW / EFW / soldados / fabricados / LSAW

Grado:alloy 625、inconel 625 、Inconel 600 、Inconel 601 、Inconel 625、Inconel 617、Inconel 690、 Inconel、718 Inconel X-750、Incoloy 800H、Incoloy 825、N02200、N02201、N04400、N08825、N06600、Monel 400 、Monel K500、N06601、N06625、N06690、N08810、N08825、N08020、N08028、N08031、N010276、N010665、N06022、N06030、GH3030、GH3036 GH5188 Inconel706 Inconel600 InconelX-750 Inconel718 Inconel625 Inconel 617 Inconel601 Inconel690 NS143 NS131 NS113 NS112,Incoloy800H, NO8810 NS111 NS336 NS142 Incoloy825 NS355 Hastelloy C-4

| Material |

Monel/Inconel/Hastelloy/Duplex Steel/PH Steel/Nickel Alloy |

| Shape |

Round,Forging,Ring,Coil,Flange,Disc,Foil,Spherical,Ribbon,Square,Bar,Pipe,Sheet |

| Grade |

N02200、N02201、N04400、N06600、N06601、N06625、N06690、N08810、N08825、N08020、N08028、N08031、N010276、N010665、N06022、N06030、GH3030、GH3036 GH5188 Inconel706 Inconel600 InconelX-750 Inconel718 Inconel625 Inconel 617 Inconel601 Inconel690 NS143 NS131 NS113 NS112,Incoloy800H, NO8810 NS111 NS336 NS142 Incoloy825 NS355 Hastelloy C-4

Monel K500,N05500 |

| Specification |

Others: 253Ma,254SMo,654SMo,F50(UNS S32100)F60,F61,F65,1J22,N4,N6 etc |

| Alloy : alloy 625,Alloy 20/28/31 |

| Hastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g; |

Hastelloy B / UNS N10001,Hastelloy B-2 / UNS N10665 / DIN W. Nr. 2.4617,Hastelloy C,Hastelloy C-4 /

UNS N06455 / DIN W. Nr. 2.4610,Hastelloy C-22 / UNS N06022 / DIN W. Nr. 2.4602,Hastelloy C-276 / UNS N10276 / DIN W. Nr. 2.4819,Hastelloy X / UNS N06002 / DIN W. Nr. 2.4665 |

| Haynes: Haynes 230/556/188; |

| Inconel Series: Inconel 600/601/602CA/617/625/690/713/718/738/X-750,Carpenter 20; |

Inconel 718 / UNS N07718 / N04400/N06600/N08825/DIN W. Nr. 2.4668,Inconel 601 / UNS N06601 / DIN W. Nr. 2.4851,

Inconel 625 / UNS N06625 / DIN W. Nr. 2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr. 2.4669,Inconel 600 / UNS N06600 / DIN W. Nr. 2.4816 |

| Incoloy: Incoloy 800/800H/800HT/825/925/926; |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 |

| Monel: Monel 400/K500/R405 |

| Nitronic: Nitronic 40/50/60; |

| Nimonic: Nimonic 75/80A/90/A263 ; |

Wire: 0.01-10mm

Strip: 0.05*5.0-5.0*250mm

Bar: φ4-50mm;Length 2000-5000mm

Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm

Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm |

Product

Characteristics |

1. According to the preparation process can be divided into deformation superalloys,

casting superalloys and powder metallurgy superalloys.

2. According to the strengthening mode, there are solid solution strengthening type, precipitation

strengthening type, oxide dispersion strengthening type and fiber strengthening type, etc.. |

| Standard |

GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Inspection |

ISO, SGS, BV, and so on. |

| Application |

High-temperature components such as turbine blades, guide vanes, turbine disks, high pressure

compressor disks, machine manufacturing

and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines |

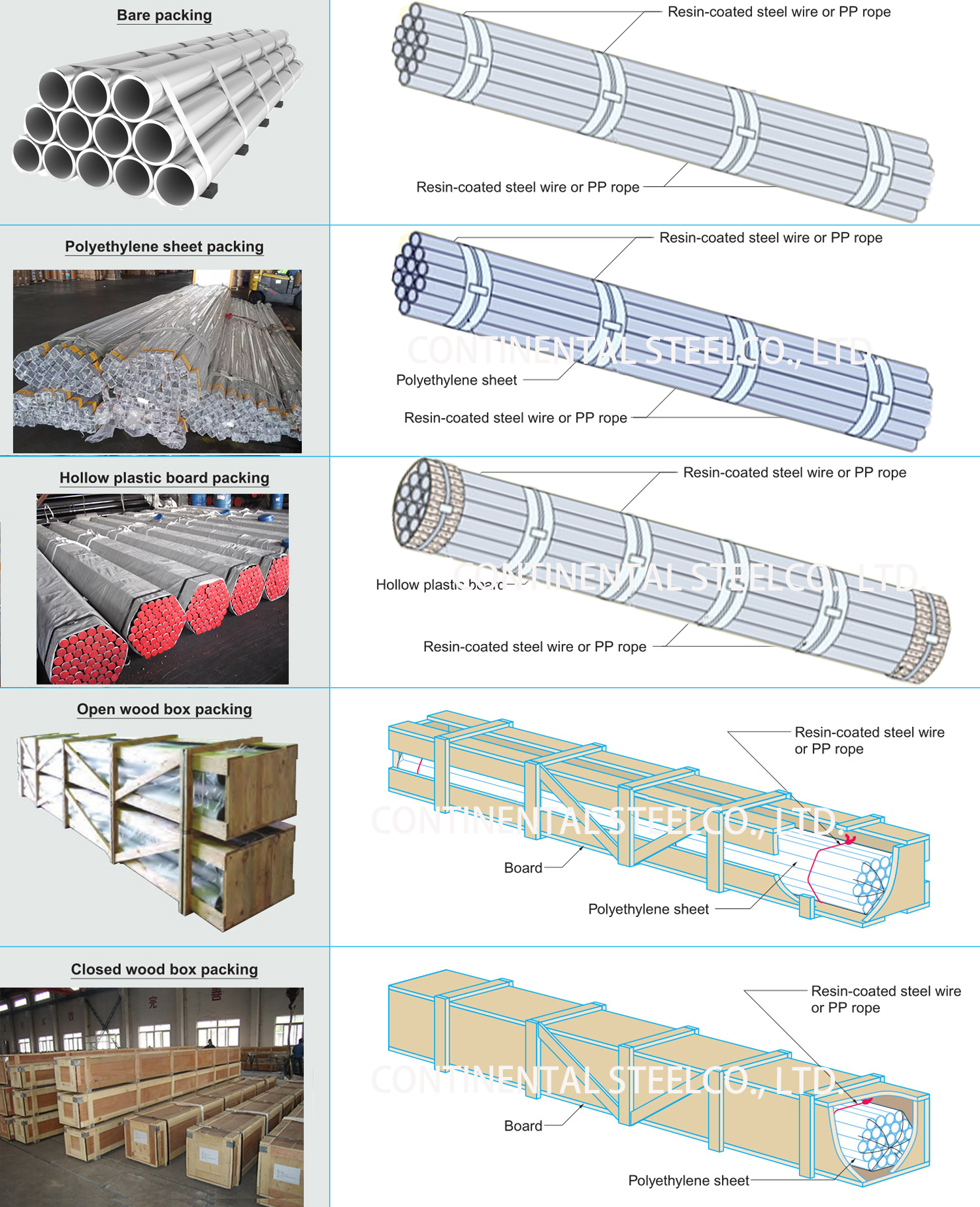

| Packaging |

1. cases packed in wooden cases

2. paper packaging

3. plastic packing

4. foam packaging

Packaging according to customer requirements or products |

Monel >> Monel 400, Monel K-500, Monel R405

barra forjada inconel 718, barra redonda inconel 718 precio, astm b637, barra redonda forjada astm b637 precio inconel 718

Inconel >> Inconel 600, Inconel 601, Inconel 625, Inconel 617, Inconel 690, Inconel 718,

Inconel X-750, Inconel 926

barra forjada inconel 718, barra redonda inconel 718 precio, astm b637, barra redonda forjada astm b637 precio inconel 718

Incoloy >> Incoloy A-286, Incoloy 800, Incoloy 800H, Incoloy 800HT, Incoloy 825, Incoloy 926, Nimonic 75, Nimonic 80A, Nimonic 263, Nimonic 90, Incoloy 901, Incoloy 925

barra forjada inconel 718, barra redonda inconel 718 precio, astm b637, barra redonda forjada astm b637 precio inconel 718

Hastelloy >> Hastelloy C-276, Hastelloy C-22, Hastelloy C-4, Hastelloy B-2, Hastelloy B-3,

Hastelloy X, Hastelloy G, Hastelloy G2, Hastelloy G3, Hastelloy G30

barra forjada inconel 718, barra redonda inconel 718 precio, astm b637, barra redonda forjada astm b637 precio inconel 718

Acero inoxidable austenítico >> 904L, Nitronic 60, XM-19, Nitronic 40, 316Ti, 316N, 316LN, 317,

317L, 310S, 253MA

barra forjada inconel 718, barra redonda inconel 718 precio, astm b637, barra redonda forjada astm b637 precio inconel 718

Acero DP >> 254SMO, F50, 2205, F53, F55 (ZEROM 100), F60, F61, F65

barra forjada inconel 718, barra redonda inconel 718 precio, astm b637, barra redonda forjada astm b637 precio inconel 718

PH Acero >> 15-5PH, 17-4PH, 17-7PH

|

Designation

|

Nearest Related Specification

|

Description

|

|

ALLOY C-276

|

ASTM B-574, 575, 619, 622, 626

|

Outstanding resistance to a variety of environments, including strong oxidisers, hot contaminated mineral acids, wet or dry chlorine contaminated media, acetic anhydride and sodium chloride solutions.

|

|

NICKEL 200

|

ASTM B160-3, BS3072: NA11

|

Commercial wrought nickel; good mech. props; excel.resistance to many corrosion environments including foods, synthetic fibres and alkalis.

|

|

MONEL*

ALLOY 400

|

ASTM B127, 163-165, BS3072-6: NA13

|

Good resistance to corrosion by sea water, dilute sulphuric, chemical, steam and petroleum plant, marine and pickling equipment.

|

|

MONEL*

ALLOY K-500

|

BS3072-6: NA18 QQ-N-286D

|

Similar corrosion resistance to Monel Alloy 400, but amenable to precipitation-hardening to give high strength. For propeller and pump shafts, bolts, doctor blades and valves.

|

|

INCONEL*

ALLOY 600

|

ASTM-B163, 166, 168, BS 3072-6: NA14

|

Combines excellent high temp strength with resistance to oxidising, carburising, nitriding and reducing atmospheres.

|

|

INCONEL*

ALLOY 601

|

|

Improved alloy where maximum high temp strength and oxidation resistance required. Good sulphidation and carburising resistance.

|

|

INCONEL*

ALLOY 625

|

ASTM B443,444,446

|

For wet corrosive, high temp and cyrogenic service. High resistance to range of corrosive solutions including acids, salts and sea water where pitting, crevice or stress cracking may occur. Excellent for overlay and dissimilar metal welds.

|

|

INCOLOY*

ALLOY DS

|

BS 3072-6: NA17

|

A general purpose heat-resisting alloy with particular resistance to carburisation and alternating carburisation and oxidation. For furnace parts, heat-treatment and vitreous enamelling equipment.

|

|

INCOLOY*

ALLOYS

800 & 800H

|

ASTM B163, 407-9, BS 3072-16: NA15

|

Resistant to chloride-ion stress-corrosion cracking, excellent high temperature strength and immunity to Sigma phase formation. Widely used for petrochemical and high temperature process equipment.

|

|

INCOLOY*

ALLOY 825

|

ASTM BI63, B423-5, BS 3072-6: NA16

|

Developed for use in aggressive corrosive environments. Exceptional resistance to corrosion by acids and alkalis in reducing or oxidising conditions. It is resistant to stress corrosion cracking and pitting and used for chemical plant and pickling plant.

|

|

DUPLEX STAINLESS

STEEL 2507

|

ASTM A240, A47 9, A959

|

2507 is a duplex stainless steel with very high strength. It has very high resistance to uniform corrosion, pitting and crevice corrosion and to stress corrosion cracking.

|

|

AUSTENITIC STAINLESS STEEL 310 (S31000)

|

ASTM A240

|

A heat resistant austenitic stainless steel with better scaling resistance than standard grades. Usable to 1035°C in intermittent service, 1150°C in continuous service

|

|

AUSTENITIC STAINLESS STEEL 253MA (S30815)

|

ASTM A240

|

253 MA is microalloyed with rare earth metals (REM) for excellent heat resistance. Best used at 850-1100°C. Can become brittle at room temperature after service at 600-850°C.

|

|

AUSTENITIC STAINLESS STEEL 254SMO (S31254)

|

ASTM A240

|

Highly corrosion resistant austenitic stainless steel containing 6% molybdenum, plus copper. Pitting resistance equivalent =43.

|

|

ALLOY 31

(N08031)

|

ASTM B625, B462, B649, B366, B626

|

An advanced super-austenitic, high-chromium 6% moybdenum corrosion resisting alloy. Bridges the cost/performance gap between Ni-Cr-Mo alloys and 300 series stainless steels. Is used in the chemical process and petrochemical industries.

|

Español

Español English

English