- HOME

- COMPAÑÍA

-

PRODUCTOS

- OCTG

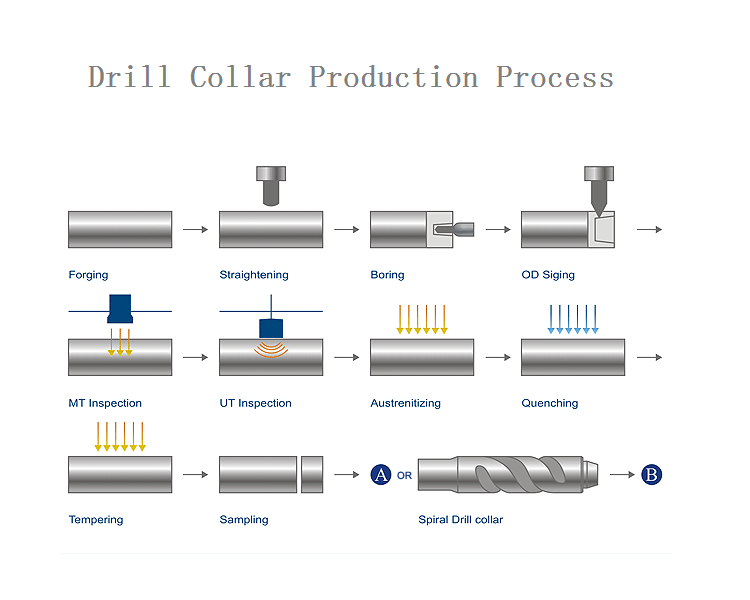

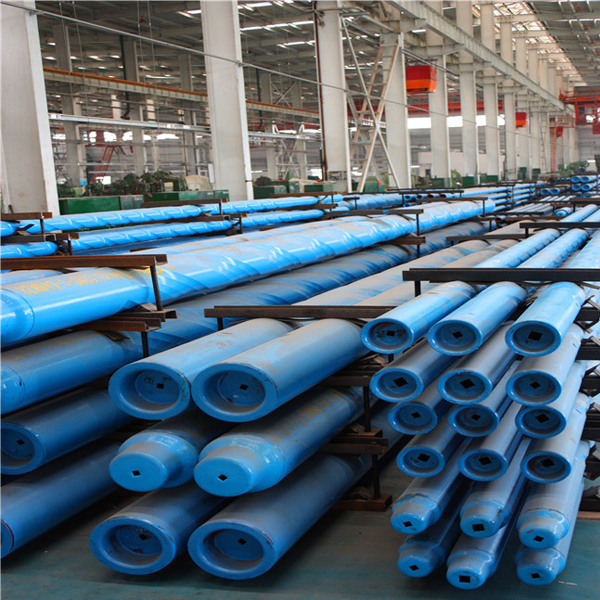

- Tubería de tubería de aceite Tubería de acero de la carcasa de aceite Varilla de bombeo Pup Joint Acoplamiento de tubería y revestimiento Collares de perforación Tubo de perforación Screen Pipe

- Tubería de acero sin costura

- Tubería de acero sin costura Tubería de acero para calderas Tubo de línea sin costura Honed Tubo Tubo de cilindro hidráulico U Tubo Tubo intercambiador de calor Tubo de baja temperatura Tubos de precisión sin soldadura Tubo mecánico sin soldadura de carbono

- Tubería de acero soldado al carbono

- Tubería de acero al carbono SSAW Tubería de acero al carbono LSAW Tubería de acero al carbono ERW

- Tubería de acero inoxidable

- Bobina de acero inoxidable Varilla/barra de acero inoxidable Tubo de acero inoxidable soldado Tubería de acero inoxidable sin soldadura

- Tubería de acero recubierta anticorrosión

- Tubería revestida de cerámica Tubo de acero revestido de caucho Tubo de acero revestido de hormigón Tubo de acero revestido 2PE/3PE Tubo de acero revestido FBE Tubo de acero galvanizado

- Tubo de acero sin costura de aleación

- Tubería de acero de aluminio tubo con aletas Tubería de acero de aleación de titanio Tubería de acero de aleación Hastelloy Tubo de acero de aleación de níquel-cobre Tubería de acero de aleación de níquel Tubería de acero de aleación

- Tubo de sección hueca de acero

- Tubo de sección hueca inoxidable Tubo de sección hueca de carbono

- CALIDAD

- SERVICIO

- PROYECTOS

- BLOGS

- CONTÁCTENOS

Español

Español English

English